How something stinky becomes something valuable

In order to obtain natural fibers for the production of natural fiber-reinforced plastics (NFRP), it is first necessary to break down the fibers from the plants. Researchers at LaNDER³ have developed a special and gentle fiber disintegration process for this purpose: Water roasting, which we recently reported on. This process produces wastewater that contains very unpleasant-smelling organic acids that initially appear to be almost unusable.

Another LaNDER³ research team is now developing energy-saving processes in Explorative Project II (material separation processes for aqueous material flows after fiber pulping) to make precisely these acids usable. For example, for the production of biogas or other recyclable materials. Processing the acids into fragrances and flavorings or bioplastics is also conceivable and is being investigated in Explorative Project II.

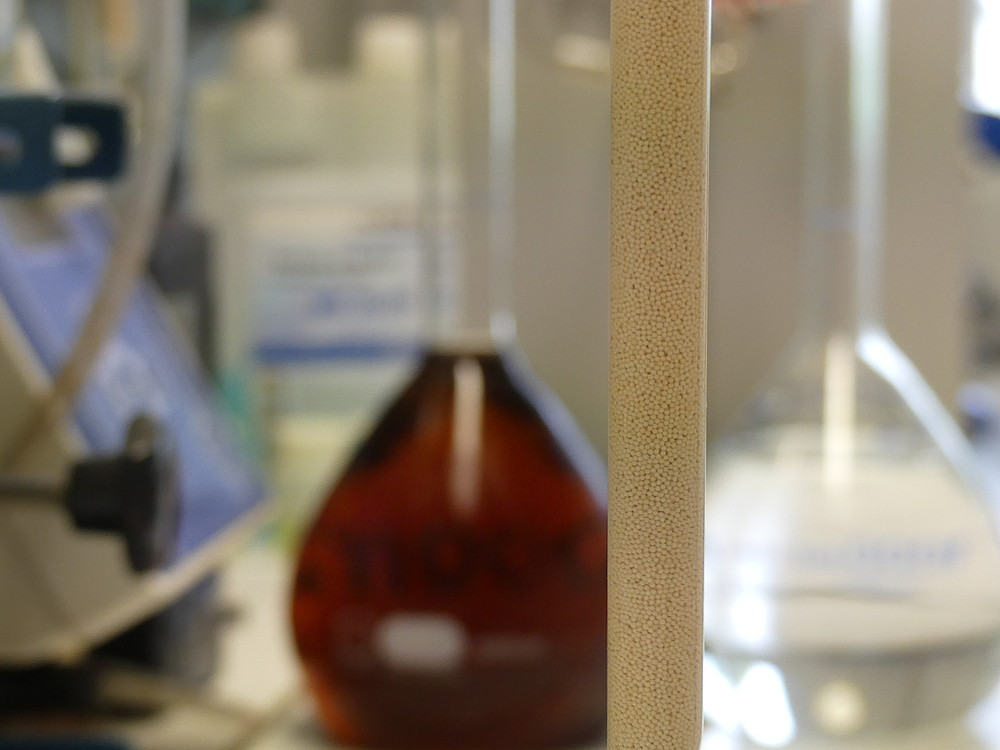

In order to utilize the acids, the researchers first separate them from the by-product of water roasting using various separating materials and then investigate their usability and economic efficiency.

The water that remains after separation is also treated by the employees and fed back into the cycle of research on natural fibers.

Like all LaNDER³ research priorities, the Explorative Project II also pursues the vision of utilizing as many by-products as possible from the production and waste treatment of NFK. All in the spirit of a circular economy.